MEMS VIBRATORY GYROSCOPES STRUCTURAL APPROACHES TO IMPROVE ROBUSTNESS FREE DOWNLOAD

Add a review and share your thoughts with other readers. The positive feedback loop destabilizes the resonator, and locks the operational frequency to the drive-mode resonant frequency. The anisoelastic forces that result in elastic coupling between the x and y axes are modeled through the off-diagonal springs constants kxy and kyx in the system stiffness matrix. Reliability requirements such as operating life, operating temperature range, thermal shock, thermal cycling, humidity, electrostatic discharge ESD immunity, and electromagnetic emissions and susceptibilities are also typically specified in many applications. The total stiffness in a certain direction could be approximated by the sum of all flexure stiffness values in that direction. User Review - Flag as inappropriate nice detail. For a generic parallel-plate electrode plate with a gap d and overlap area Aoverlap , the capacitance is Aoverlap 5.

| Uploader: | Vukasa |

| Date Added: | 4 January 2013 |

| File Size: | 50.17 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 92480 |

| Price: | Free* [*Free Regsitration Required] |

Advanced Search Find a Library.

This phenomenon occurs when a plate slides over a viscous medium and the hydrodynamic lift due to the plate velocity generates a force orthogonal to the motion direction. Sidewall tilt in DRIE is known to result in a non-rectangular cross-section, causing the principle axes of elasticity of immprove suspension beams to deviate from perfectly parallel and orthogonal to the device surface.

The remaining photoresist is stripped away. The oxide layer underneath the areas without perforation is not exposed to HF and remains intact to serve as mechanical anchors. In homoepitaxy, the deposited film follows the identical lattice structure and orientation identical to the seed crystal.

Bulk micromachining traditionally implies the use of subtractive processes to pattern thick structural layers. By designing an enclosed polysilicon via window on the proof mass, access of the etchant to the sacrificial oxide layer is prevented, preserving the oxide layer between the polysilicon layers for added mass.

The average over a specified time of gyro output measured at specified operating conditions that has no correlation with input rotation. Severe vibration environments in many applications could easily excite an undesired mode that could lead to a large bias error, saturation and even catastrophic failure. If we denote the normal direction as the y-axis and the nominal gap as y0 as in Figure 5.

In a simple single-mass design, mC is usually equal to md. The primary objective of the dynamical system is to form a vibratory drive oscillator, coupled to an orthogonal sense accelerometer by the Coriolis force. In the purely torsional mode, vibratoory boundary conditions of the beam are such that the moving end of the beam remains parallel to the fixed end, but rotates about the axis normal to the end plane.

Photoresist is coated on the device layer, and patterned using the device mask aligning to the cavity pattern on the substrate. The Coriolis moment is about the axis cross-product of the input angular rate and the drive angular velocity vectors. The straight line of oscillation due to quadrature turns into a narrow ellipse in the presence of an angular rate input.

MEMS Vibratory Gyroscopes: Structural Approaches to Improve Robustness

Pre-molded cavity packages or gel diecoatings have been developed to alleviate stress issues in plastic packages. One of the primary process differences would be the use of a bonding technique compatible with two silicon wafers such as fusion bonding.

A widely used method to deposit the photoresist on wafers is spinning or spin coating. Turner and Peter G.

Lid sealing of ceramic packages using fluxless solder preforms is known to provide sufficiently low leak rates. The dynamics and principle of operation can be best understood by considering the rotation-induced Coriolis force acting on a body that is observed in a rotating 2. If the Coriolis force frequency, and thus the drive-mode resonant frequency, is matched with the sense- 22 2 Fundamentals of Micromachined Gyroscopes mode resonant frequency, the Coriolis force excites the system into resonance in the sense direction.

CopyrightAmerican Institute of Physics.

MEMS vibratory gyroscopes : structural approaches to improve robustness (Book, ) []

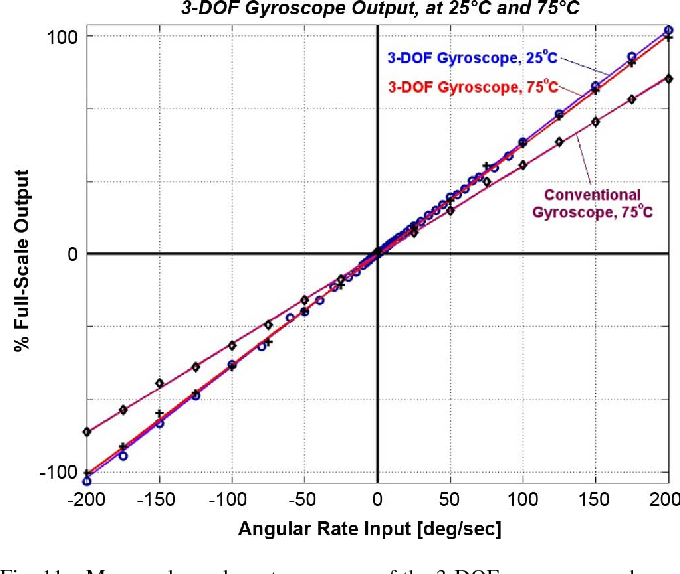

After etching the polysilicon, the photoresist is stripped. Then the image on the tsructural is projected onto a photosensitive material deposited on bibratory wafer, commonly known as photoresist. In micromachined vibratory rate gyroscopes, the mode-matching requirement renders the system response very sensitive to variations in system parameters due to fabrication imperfections and fluctuations in operating conditions.

The essence of all micromachining techniques is successive patterning of thin structural layers on a substrate. In MEMS, many factors such as the desired sidewall and bottom surface profiles, isotropy, or stiction issues determine the required etching method.

In gyroscopes, the highest stress concentration points are usually suspension beam connections. It introduces structural designs that provide inherent robustness against structural and environmental variations.

Regardless of the process, the primary advantages of dry etching are flexibility in etch profile parameters, and avoiding the surface tension effects approavhes liquid etchants that vibratroy cause stiction. The automotive industry applications are diverse, including advanced automotive safety systems such as electronic stability control ESChigh performance navigation and guidance systems, ride stabilization, roll-over detection and prevention, and next generation airbag and brake systems.

It also allows the use of single crystal silicon as the device material, which provides excellent mechanical stability.

Comments

Post a Comment